High Reliability, Cost Effective,

5 Days Ship Out

-

PRODUCT

-

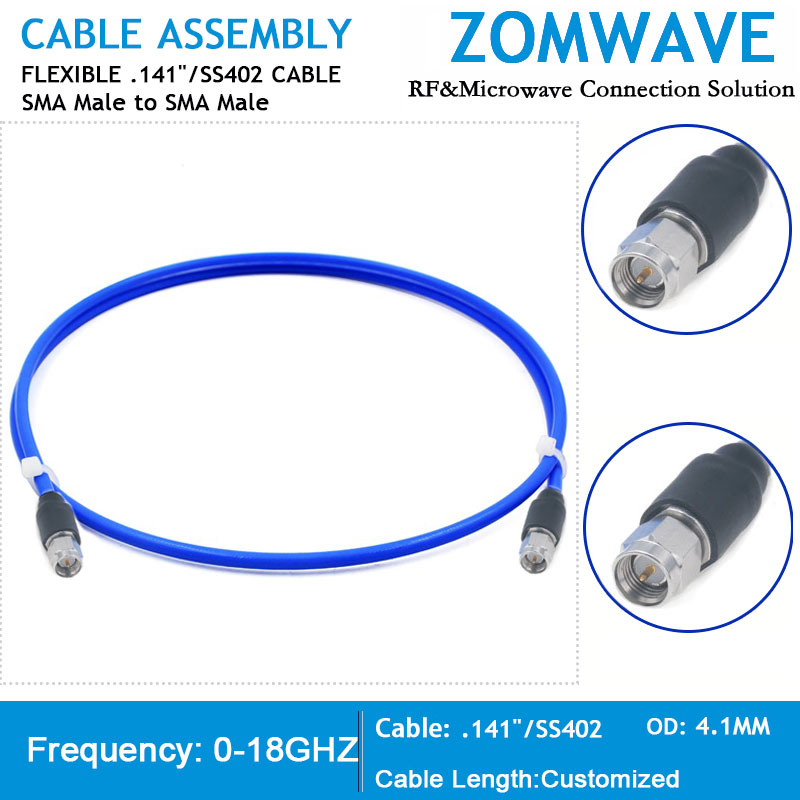

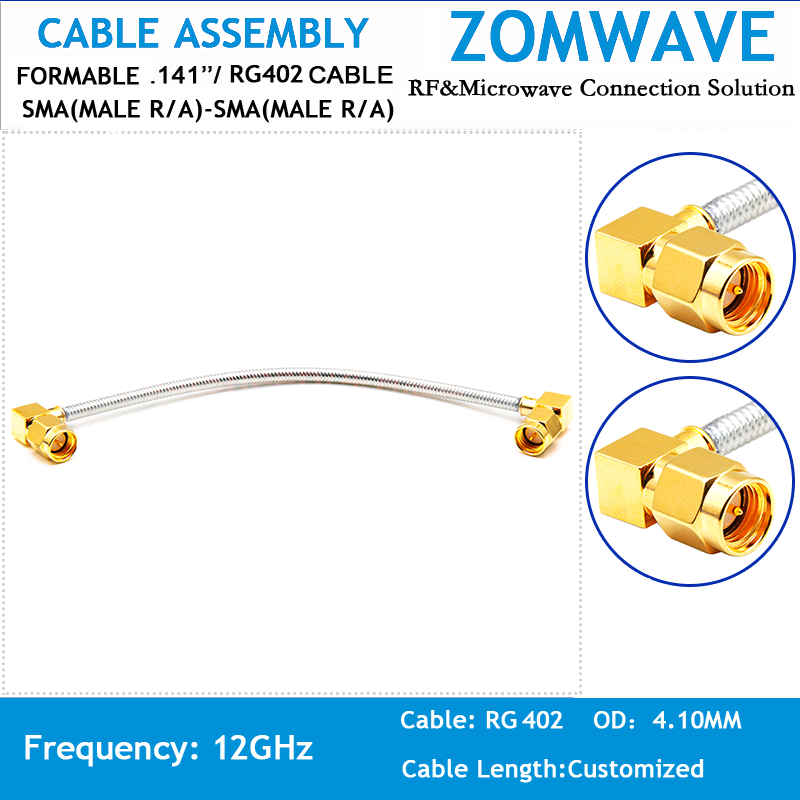

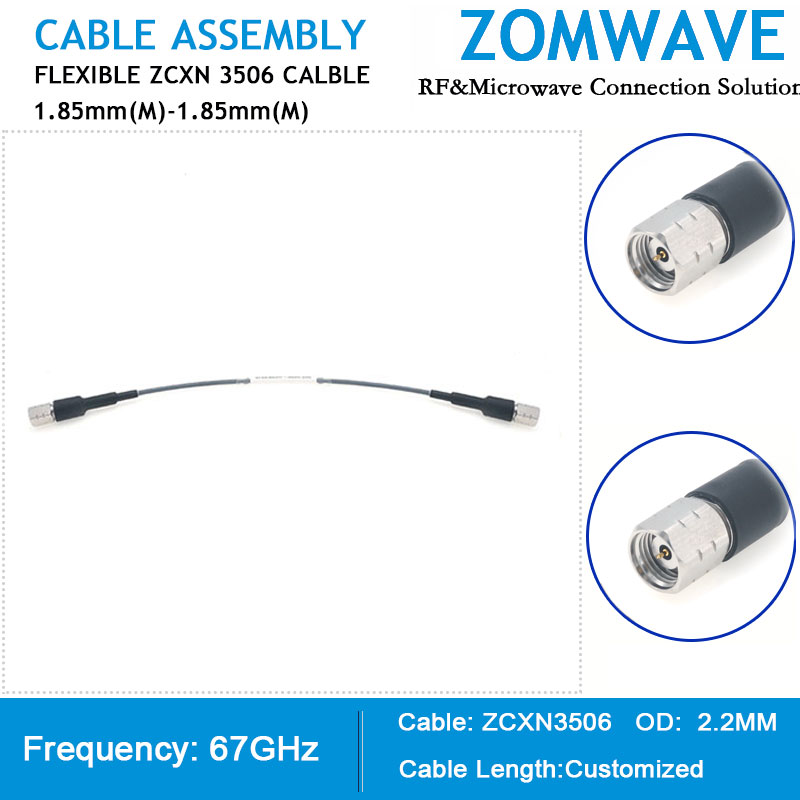

Coaxial Cable Assembly

-

Multi-coaxial Cable Assembly

-

Semi-Rigid Cable Assembly

-

LMR Series Cable Assemblies

-

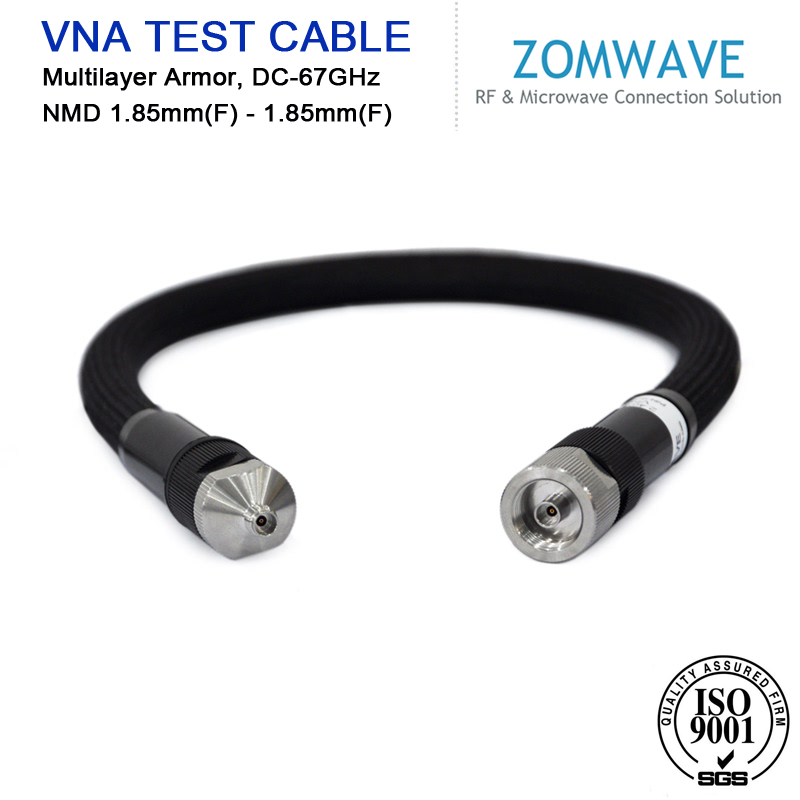

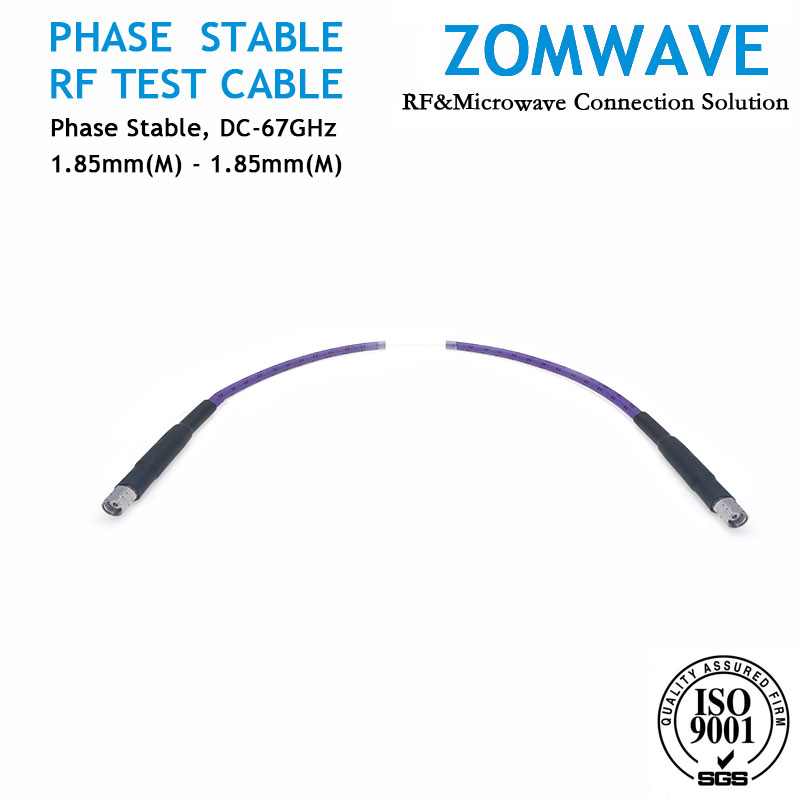

1.85mm to 1.85mm Cable Assembly

-

1.85mm to 2.4mm Cable Assembly

-

1.85mm to 2.92mm Cable Assembly

-

1.85mm to Mini SMP (SMPM/GPPO) Cable

-

2.4mm to 2.4mm Cable Assembly

-

2.4mm to 2.92mm Cable Assembly

-

2.4mm to Mini SMP (SMPM/GPPO) Cable

-

2.92mm to 2.92mm Cable Assembly

-

2.92mm to Mini SMP (SMPM/GPPO) Cable

-

2.92mm to SMP (GPO) Cable Assembly

-

2.92mm to SMA Cable Assembly

-

3.5mm to 3.5mm Cable Assembly

-

3.5mm to SMP Cable Assembly

-

3.5mm to SMA Cable Assembly

-

SMP to SMA Cable Assembly

-

SMP to Type N_TNC_BNC Cable Assembly

-

Mini SMP to Mini SMP Cable Assembly

-

Mini SMP to SMP Cable Assembly

-

Mini SMP to SMA Cable Assembly

-

SMA to TNC Cable Assembly

-

SMA to SMA Cable Assembly

-

SMP to SMP Cable Assembly

-

SMA to SSMA Cable Assembly

-

SMA to Type N Cable Assembly

-

SMA to SMB Cable Assembly

-

SMA to MCX Cable Assembly

-

SMA to MMCX Cable Assembly

-

SMA to SSMB Cable Assembly

-

SMA to BNC Cable Assembly

-

Type N Cable Assembly

-

Type N to MCX Cable Assembly

-

Type N to MMCX Cable Assembly

-

Type N to TNC Cable Assembly

-

Type N to BNC Cable Assembly

-

Type N to SMB Cable Assembly

-

TNC Cable Assembly

-

BNC Cable Assembly

-

FAKRA Cable Assembly

-

MCX Cable Assembly

-

MMCX Cable Assembly

-

SMB to SMB Cable Assembly

-

SMB to SMC Cable Assembly

-

SMB to MMCX Cable Assembly

-

SMB to MCX Cable Assembly

-

SMC to SMC Cable Assembly

-

SSMC to SSMC Cable Assembly

-

IPEX(UFL) Cable Assembly

-

IPEX(UFL) To SMA Cable Assembly

-

-

Coaxial RF Connector

-

Microwave Test Cable

-

Coaxial RF Adapter

-

1.85mm to 1.85mm Adapter

-

1.85mm to 2.4mm Adapter

-

1.85mm to 2.92mm Adapter

-

2.4mm to 2.4mm Adapter

-

2.4mm to 2.92mm Adapter

-

2.4mm to 3.5mm Adapter

-

2.4mm to Type N Adapter

-

2.92mm to 2.92mm Adapter

-

2.92mm to 3.5mm Adapter

-

2.92mm to SSMA Adapter

-

2.92mm to Type N Adapter

-

3.5mm to 3.5mm Adapter

-

3.5mm to SSMA Adapter

-

3.5mm to BMA Adapter

-

3.5mm to SBMA Adapter

-

3.5mm to Type N Adapter

-

3.5mm to 7mm Adapter

-

SMP to 2.4mm Adapter

-

SMP to 2.92mm Adapter

-

SMP to 3.5mm Adapter

-

SMP to SMA Adapter

-

Mini SMP to 2.4mm Adapter

-

Mini SMP to 2.92mm Adapter

-

Mini SMP to SSMA Adapter

-

Mini SMP to SMA Adapter

-

SMA to SMA Adapter

-

SMA to Type N Adapter

-

SMA to SMB Adapter

-

SMA to SMC Adapter

-

SMA to SSMC Adapter

-

SMA to MCX Adapter

-

SMA to MMCX Adapter

-

SMA to IPEX Adapter

-

SMA to BNC Adapter

-

SMA to TNC Adapter

-

SMA to RP-SMA Adapter

-

Type N to Type N Adapter

-

Type N to TNC Adapter

-

Type N to BNC Adapter

-

Type N to RP-SMA Adapter

-

TNC to TNC Adapter

-

TNC to BNC Adapter

-

BNC to BNC Adapter

-

75ohm to 50hom Adapter

-

NMD Adapter

-

-

Coaxial RF Test Probe

-

Coaxial RF Terminator/Load

-